Reducing CO₂ using waste wood

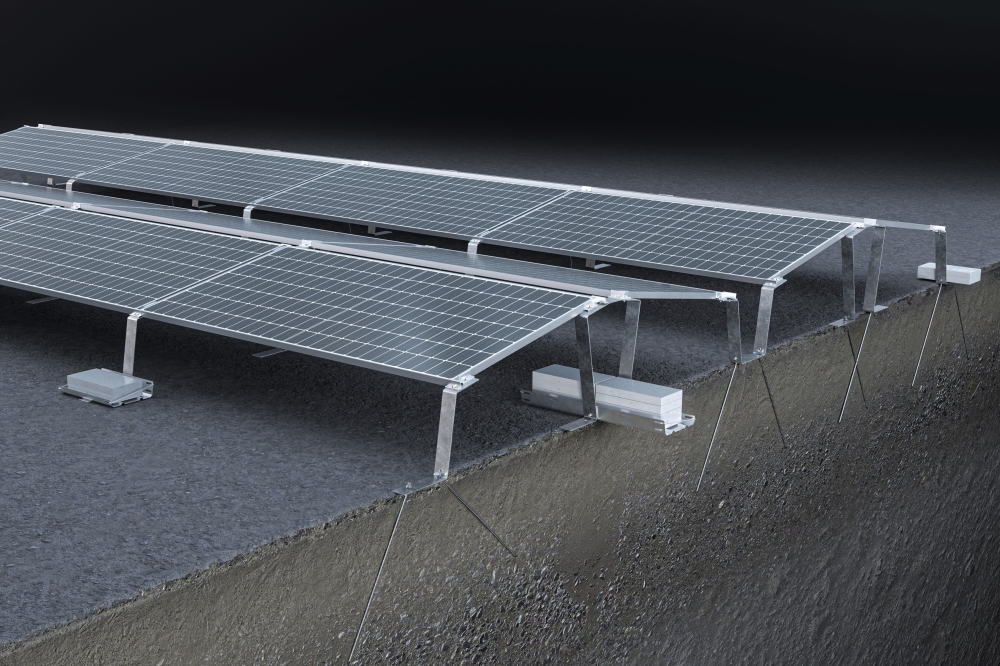

The Dinslakener Holzenergiezentrum (Dinslaken Wood Energy Centre, DHE) is considered a milestone in the sustainability strategy of Stadtwerke Dinslaken. Using state-of-the-art technology from Doosan Lentjes, waste wood is efficiently used to generate electricity and heat – a decisive contribution to a climate-friendly energy supply for the region.

The DHE replaces the former Walsum 9 coal-fired power plant and is firmly committed to renewable energies. The combustion of waste wood saves around 125,000 tonnes of CO₂ annually. The two-line plant offers redundancy and high flexibility to reliably cover district heating demand and carry out scheduled maintenance work without interrupting supply. A modern flue gas cleaning system ensures that all emission limits are reliably complied with.

As part of the turnkey contract, Doosan Lentjes was responsible for the delivery, installation and commissioning of the two incineration process lines. The technology used was specially adapted to the requirements of the project and the use of waste wood.