Building a sustainable solar lifecycle: From design to recycling

The solar photovoltaic (PV) sector is crucial to the global energy transition. According to research from the International Energy Agency (IEA), solar power is expected to become the largest renewable energy source by 2029, accounting for 80% of the growth in global renewable capacity.

Yet, concerns persist about the long-term sustainability of the panels themselves — particularly what happens to them at the end of their useful life. Research from the International Renewable Energy Agency (IRENA) forecasts that waste from discarded panels could total 78 million tonnes by 2050, highlighting the scale of the potential issue.

Storing this clean energy will also be central to meeting net zero objectives. Electricity demand in the UK is set to increase by around 50% by 2035, highlighting the importance of retaining power to use during periods of peak usage. Similarly to solar PV, materials used for the infrastructure that enables energy storage should not damage the environment in the long term.

As an industry, the energy sector has a responsibility to ingrain sustainable principles at every stage of the product lifecycle to offset this risk, from research and development to production and deployment.

Ultimately, products should be designed with environmental sustainability in mind from their very inception, to ensure that clean energy continues to support long-term net zero objectives. This can be achieved by focusing on three areas: design, manufacturing and utilisation.

Product design

Before a product even reaches the production line, PV and storage companies should already understand which steps they should take to ensure the goods they produce are sustainable.

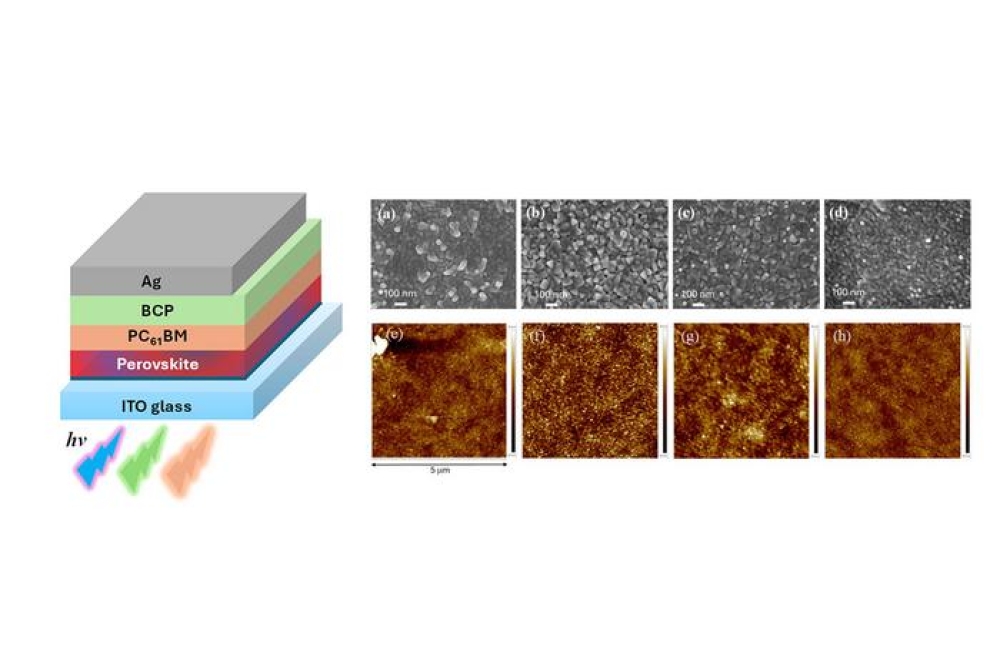

In solar PV, adopting a lightweight design ensures optimal product performance and photoelectric conversion efficiency. This can be achieved through the introduction of low-weight adhesive films and the reduction of silicon material usage, minimising resource consumption from the beginning of the process.

Extensive research into the use of eco-friendly materials—such as recycled aluminium—should be a priority to maximise resource efficiency and reduce carbon emissions, both for PV modules and storage technology. At the same time, developing technical alternatives that reduce or eliminate harmful substances is essential to minimising environmental impact.

Through technological innovation, PV companies can continuously enhance the photoelectric conversion efficiency of their products, boost electricity generation and storage capacity throughout the product's entire lifecycle and fortify durability to extend the product lifespan.

Product manufacturing

In manufacturing of both PV modules and batteries, the clean energy industry is moving decisively toward clean, low-carbon production. Water and energy-saving practices, equipment upgrades, and process optimisation are all contributing to more efficient and responsible operations.

This commitment is achieved through the elimination of high-energy-consuming and high-water-consuming equipment, modification of existing equipment, and optimisation of production processes. The effective utilisation of wastewater, waste gas, waste liquid, and other waste, can also reduce the generation of pollutants.

Success in manufacturing hinges on consistently reviewing internal processes to guarantee performance remains high. This includes maintaining multi-dimensional, stringent and systematic environmental certification standards at production bases, accelerating a permanent shift to green production.

Product circulation, use and recycling

To further reduce the environmental impact of value chain activities, solar PV and storage providers should implement measures such as optimising logistics systems, exploring opportunities for recycling, and actively researching methods for better deploying resources during the product scrapping phase. These efforts drive collaboration with partners to enhance green management processes.

Green logistics can significantly reduce the environmental impact of clean energy companies. By optimising transportation routes and methods, improving loading rates, and promoting new energy transportation tools, solar providers can build a low-carbon and efficient logistics system, making freight transportation much less harmful to the environment.

Additionally, when facing the decision between product repair or replacement, we advocate for a dual assessment from both economic and environmental perspectives, striving to achieve an optimal balance between cost-effectiveness and ecological sustainability.

Establishing a robust recycling and reuse infrastructure for decommissioned PV modules and batteries is key to unlocking a scalable, circular model for the solar industry. This requires companies to work closely with all partners throughout the industry chain to ensure technical challenges are overcome, and that consistent, thorough practices are in place to maximise the recycling capabilities of products.

It's crucial that solar manufacturers understand that they are still responsible for their products once they have left the warehouse. Establishing an ecosystem where like-minded companies work in tandem to promote green practices will secure the industry’s future.

Understanding the regulatory landscape

There are a host of regulatory initiatives – some compulsory, others optional – that support the creation of feasible long-term business models. Complying with the EU's Waste Electrical and Electronic Equipment Directive (WEEE Directive) and the EU's Regulation on Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH Regulation), is essential for the sector’s incumbents.

Further steps that can be taken include cooperating with take back and waste management schemes to establish a recycling and processing mechanism for PV modules. Similarly, assisting customers in recycling and reusing solar modules or storage infrastructure that need to be replaced or have reached the end of their life reduces the environmental impact of waste while maximising resource utilisation.

Sustainable from start to finish

For solar PV and energy storage to reach their full potential, sustainability must be embedded throughout the entire product lifecycle—from design and manufacturing to installation, use, and decommissioning. Combined with ongoing technological advances in terms of module efficiency and capability, this will help unlock the full potential of solar power and enable this energy source to be the driving force of the net zero transition.